What are the different kind of fiber optic patch cords? Leave a comment

What are the different kind of fiber optic patch cords?

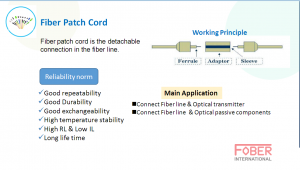

Fiber optic patch cord is composed of fiber optic cable terminated with different premium grade ferrule connectors on both ends.

They are manufactured and tested in compliance with TIA 604 (FOCIS), IEC 61754 and YD/T industry standards. OM1, OM2, OM3, OM4, OM5 or OS2 fiber types are available to meet the demand of Gigabit Ethernet, 10 Gigabit Ethernet and high speed Fiber Channel. Every termination is through rigorous parameter test to ensure the hightest network performance.

Application of patch cords

Data centre, Enterprises, Fttx, Lan, Wan, Catv network, Telecom network applications

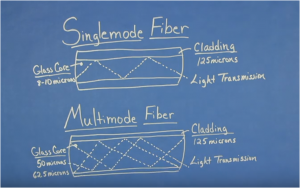

Difference based on mode

| NAME | DESCRIPTION | PICTURE |

| Single mode fiber patch cord |

|

|

| Multimode fiber patch cord |

|

|

| 10gig multimode fiber optic patch cord |

|

|

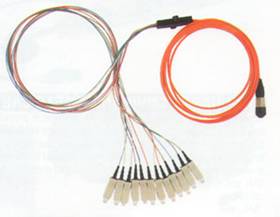

Difference based on the structure

Difference in Fiber optic patch cord based on connectors of each end

- Same connector type fiber patch cable:This fiber optic patch cable has the same type of connector on both ends, such as ST, SC, LC, FC, etc.

- Hybrid fiber optic patch cables:This fiber optic patch cable has different connectors on each end. One end can be SC and the other end can be LC, ST, FC, etc.

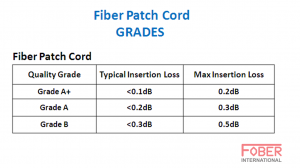

Difference in Fiber optic patch cord based on connection polishing types

Connector Polishing Types: Fiber optic connectors are designed and polished to different shapes to minimize back reflection. This is particularly important in single mode applications. Typical back reflection grades are -30dB, -40dB, -50dB and -60dB. Refer to this connector fiber polish types document for more information.

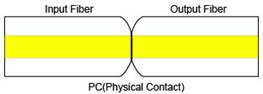

PC (Physical Contact): Typical back reflection <-40dB, for single mode and multimode applications.

UPC (Ultra Physical Contac t):Typical back reflection <-50dB, for single mode applications.

APC (Angled Physical Contact):Typical back reflection <-60dB, for single mode applications.

Difference in Fiber optic patch cord size.

250um bare fiber, 900um tight buffer fiber, 1.6mm fiber optic cable, 2.0mm fiber optic cable, 3.0mm fiber optic cable

| Feature: | Picture | |

| FC:

Metal sleeves,turnbuckle high-strength metal shell,locked structure in thread. Often used with test equipment. |

|

|

| SC:

Plug type connector,rectangular structure,flexibility locking structure,used to ODN,FTTX. Insertion and evulsion structure,ensures high density and repeat connectivity. |

|

|

| ST:

Bayonet locking mechanism makes it quick and easy to use. ST connectors are cylindrical with twist lock coupling. They are push-in and twist type. It is still commonly used for multi-mode networks. |

|

|

| LC:

Insertion and evulsion fiber patch cord,with miniature plug rectangular and flexible locking structure. Small size,light weight,pin and sleeve adapted are half the size of the SC,FC. Duplex patch cords features a snap-on clip making later re-positioning possible |

|

|

| Physical Characteristics | Description |

| Connector Types End A | LC/SC/ST/FC/LSH/MTRJ/MU |

| Connector Types End B | LC/SC/ST/FC/LSH/MTRJ/MU |

| Polish Type | SMF: UPC-UPC; UPC-APC; APC-UPC; APC-APC;

MMF: UPC-UPC |

| Connector Ferrule | Zirconia Ceramic |

| Cable Outside Diameter | 0.9mm/2.0mm/3.0mm |

| Interchangeability+

|

≤0.2dB |

| Vibration | ≤0.2dB |

| Minimum Bend Radius | SMF: 10mm; MMF: 7.5mm/15mm |

| Mechanical Characteristics | Description |

| Fiber Type

|

OS2/OM5/OM4/OM3/OM2/OM1 |

| Fiber Count | Simplex/Duplex |

| Cable Jacket | PVC (Riser/OFNR)/LSZH/Plenum (OFNP) |

| Jacket Color | OM1/OM2: Orange; OM3/OM4: Aqua;

OM5: Lime Green; OS2: Yellow |

| Fiber Grade | SMF: G.657.A1;

OM5/OM4/OM3/OM2: Bend Insensitive; OM1: G.651 |

| Optical Characteristics | Description |

| Connector Insertion Loss | SMF: LC/SC/ST/FC/MU/LSH≤0.3dB;

MMF: LC/SC/ST/FC/MU≤0.3dB; LSH≤0.4dB |

| Connector Return Loss | SMF: UPC≥50dB; APC≥60dB; MMF: ≥20dB |

| Attenuation at 1310nm | 0.36dB/km |

| Attenuation at 1550nm | 0.22dB/km |

| Attenuation at 850nm | 3.0dB/km |

| Attenuation at 1300nm | 1.0dB/km |

| Environmental Characteristics | Description |

| Operating Temperature | -20~80℃ |

| Storage Temperature | -40~80℃ |

CLEANING METHODS FOR FIBER OPTIC PATCH CABLES

- Always inspect the connector first! Then determine the cleaning action. Inspect the connector after cleaning and repeat cleaning steps, as necessary.

- Use dry cleaning for light debris, dust, or black spots– Use a dry wipe with a cleaning cloth or reel cleaner. If the contaminant can’t be removed by dry cleaning, use the wet cleaning method.

- Use wet cleaning for oily or grease-like contamination– Use a cleaning cloth or reel cleaner that is slightly wetted by a special cleaning liquid

- Don’t reuse cleaning materials

To see the product details click here